Engineering Autonomy at Scale

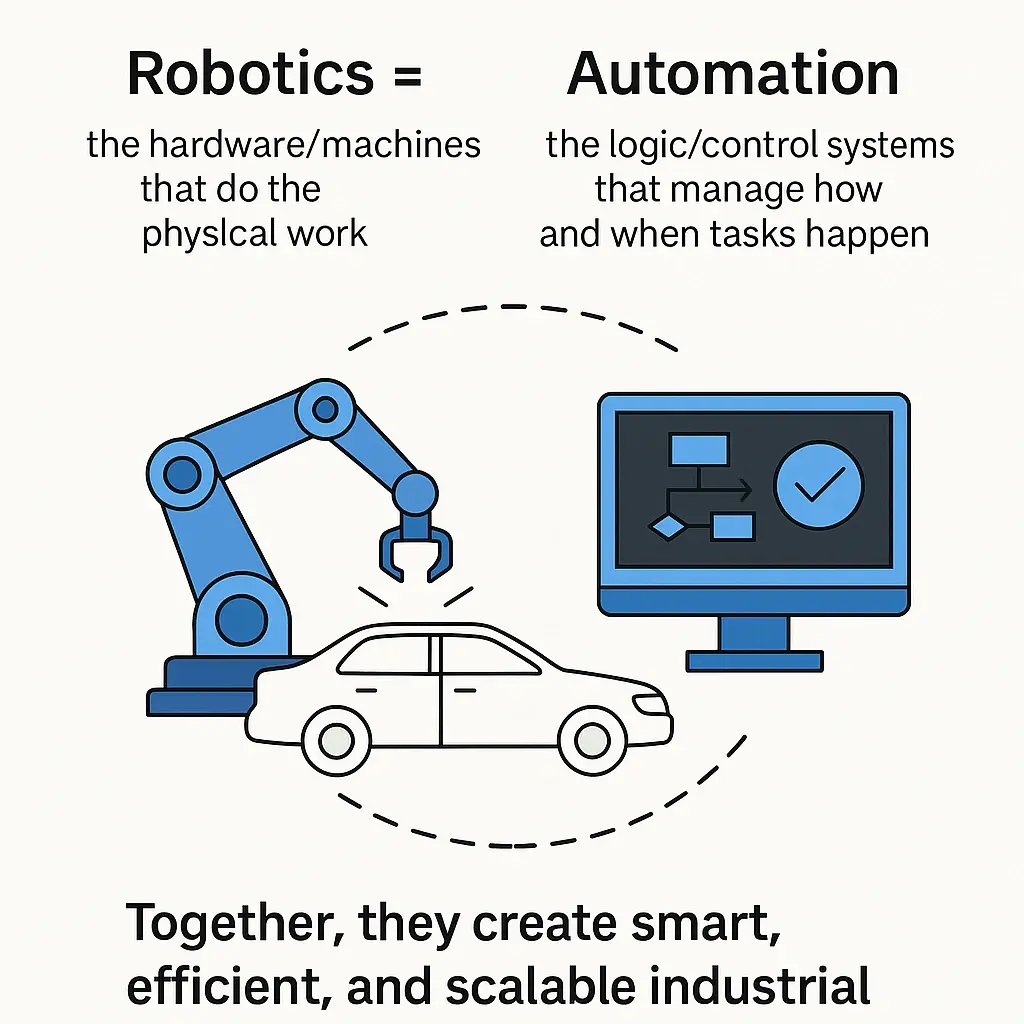

At IVIS, we empower industrial organizations to achieve operational independence and intelligent system control through purpose-built robotics and automation solutions. Whether you're optimizing a single production line or managing multi-national operations, our scalable architectures deliver consistency, intelligence, and long-term ROI.

For Local & Regional Enterprises

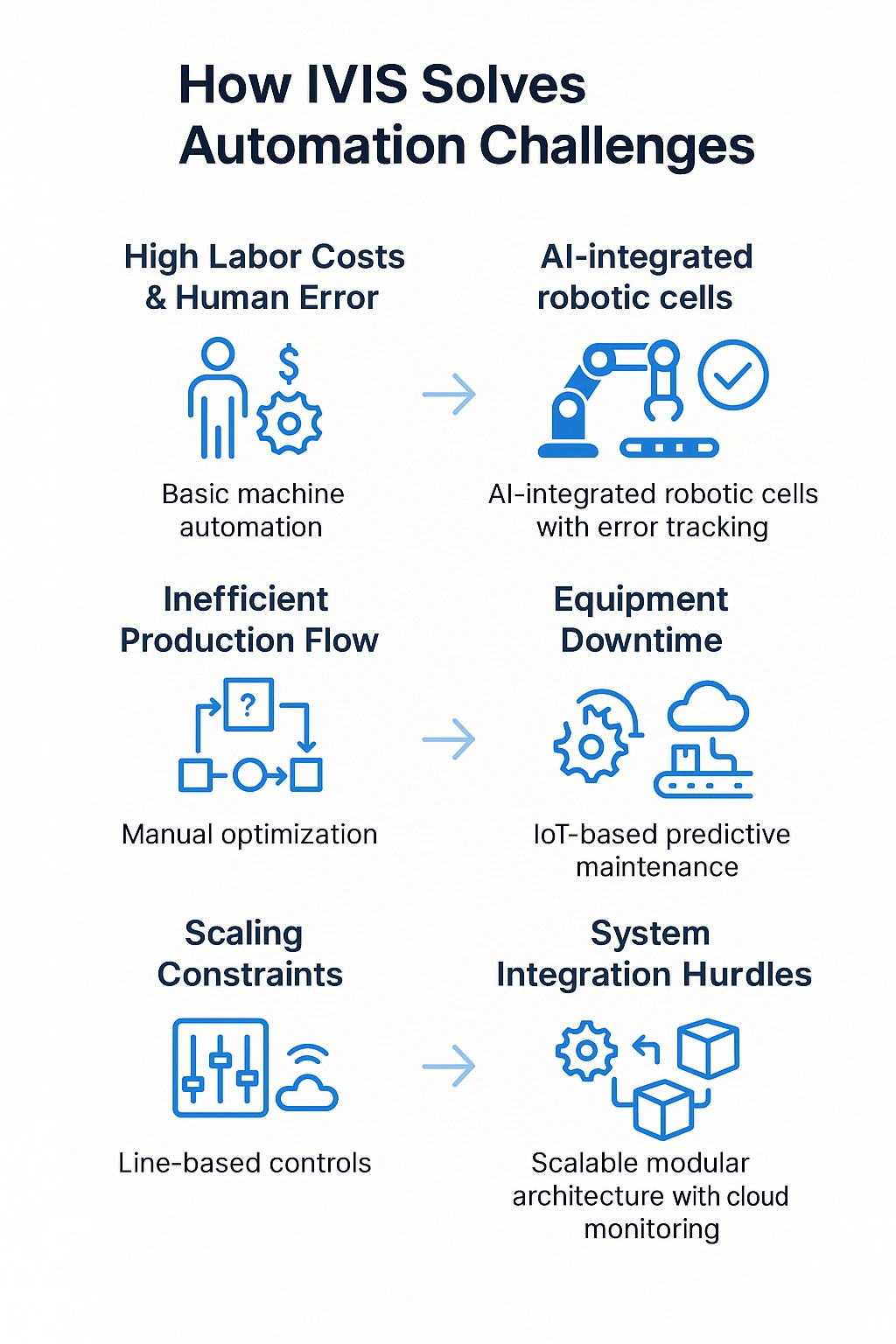

Small to mid-sized businesses often struggle with high labor costs, manual errors, and inconsistent output. IVIS addresses these issues by introducing right-sized automation solutions tailored to local operational realities.

We deploy compact robotics, sensor-triggered workflows, and programmable logic control to:

• Replace repetitive manual tasks with robotic precision

• Enhance product consistency and reduce defect rates

• Improve shift productivity and energy/resource efficiency

• Enable easier quality control and traceability

• Lay the groundwork for scalable future automation

Our focus is on enabling local enterprises to take their first step toward smart manufacturing—without the complexity or cost of over-engineered solutions.

For Hybrid Facilities & Multi-Site Operations

In facilities transitioning between manual and fully automated processes, consistency and coordination become critical. IVIS supports hybrid operations through modular robotics frameworks and cross-location automation logic, engineered for central visibility and adaptive control.

We help you:

• Deploy PLC-driven automation to selected lines or units

• Integrate robotics with SCADA, MES, or ERP platforms

• Monitor multi-site production KPIs in real time

• Enable smart alarms, remote overrides, and task scheduling

• Phase in automation without disrupting existing systems

This is ideal for organizations managing different maturity levels across plants or regions—where stepwise automation needs to align with cost, capacity, and control policies.

For International Industrial Conglomerates

For global enterprises, automation must be industrial-grade, compliant, and seamlessly integrated with enterprise infrastructure. IVIS provides complete robotic and control system deployments aligned with international standards such as IEC, ISO, and OSHA.

Our enterprise automation services include:

• AI-driven robotic lines with built-in quality assurance

• Remote operation, diagnostics, and predictive maintenance

• Scalable robotic cell deployment across geographies

• End-to-end system integration (ERP–MES–PLC–SCADA)

• Cyber-physical system design and digital twin enablement

We specialize in complex environments where robotics and automation must not only function independently but also harmonize with global compliance, reporting, and risk control frameworks.